Explain Why A Seesaw Is Closest In Arrangement To A First Class Lever.

When observing playground equipment, a seesaw stands out as a simple yet fascinating contraption. It’s not just a toy but a practical example of fundamental physics principles. If you’ve ever wondered how a seesaw works, you might be interested to know that it is explain why a seesaw is closest in arrangement to a first class lever. In this article, we will explain why a seesaw is closest in arrangement to a first class lever, breaking down the mechanics and comparing it with other types of levers.

Whtat is explain why a seesaw is closest in arrangement to a first class lever.

A explain why a seesaw is closest in arrangement to a first class lever. because of the way its components are positioned and function. In a first-class lever, the fulcrum is placed between the effort and the load. This setup allows for a balanced and efficient movement of forces. Similarly, a seesaw has a central pivot point, or fulcrum, located between two ends where the load (a person’s weight) and the effort (the force exerted by another person) are applied. This arrangement enables the seesaw to move up and down smoothly, much like how a first-class lever operates, by balancing the forces around the central point.

| Aspect | Seesaw | First-Class Lever |

|---|---|---|

| Fulcrum Position | Fulcrum is at the center of the seesaw | Fulcrum is between the effort and the load |

| Effort Application | Person applies force on one end of the seesaw | Force is applied on one side of the lever |

| Load Placement | Opposite person acts as the load | Load is positioned on the other side of the fulcrum |

| Balance Principle | Balance is achieved by equalizing forces on both sides | Balances by distributing effort and load around the fulcrum |

| Movement | Up-and-down motion depending on force applied | Moves based on the relative force and position of load and effort |

| Example | Playground seesaw | Scissors, crowbar, balance scale |

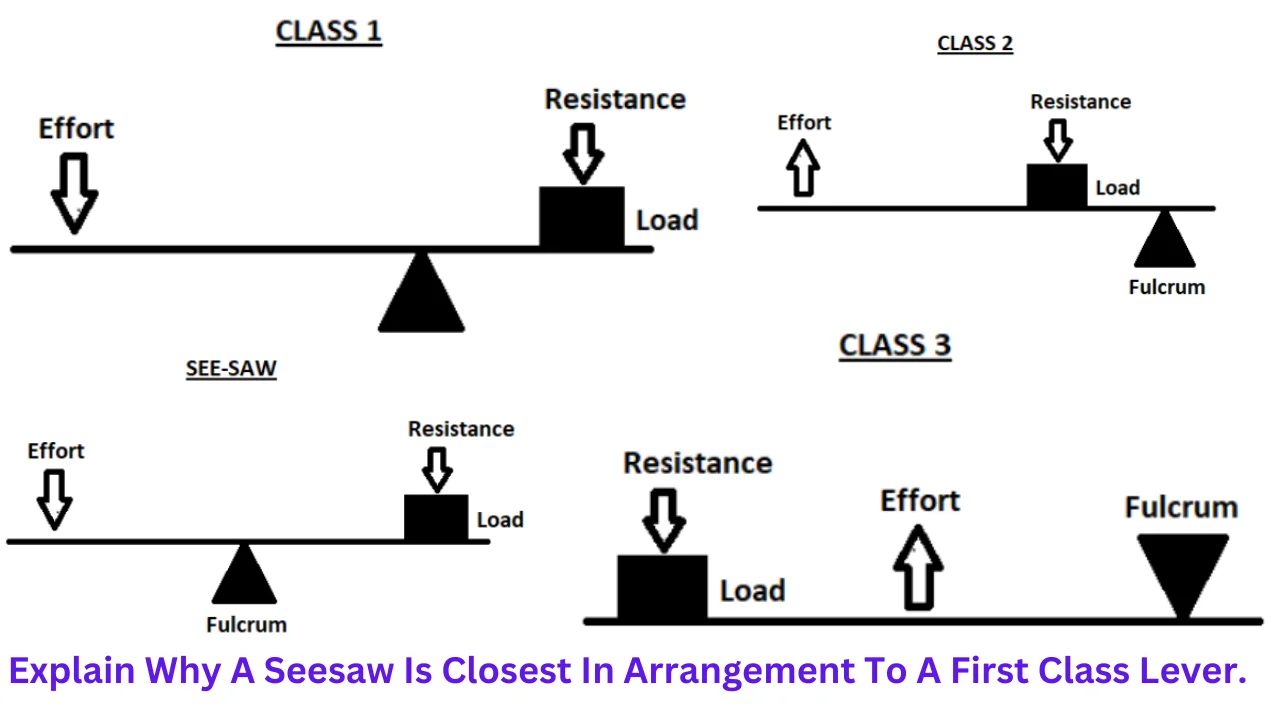

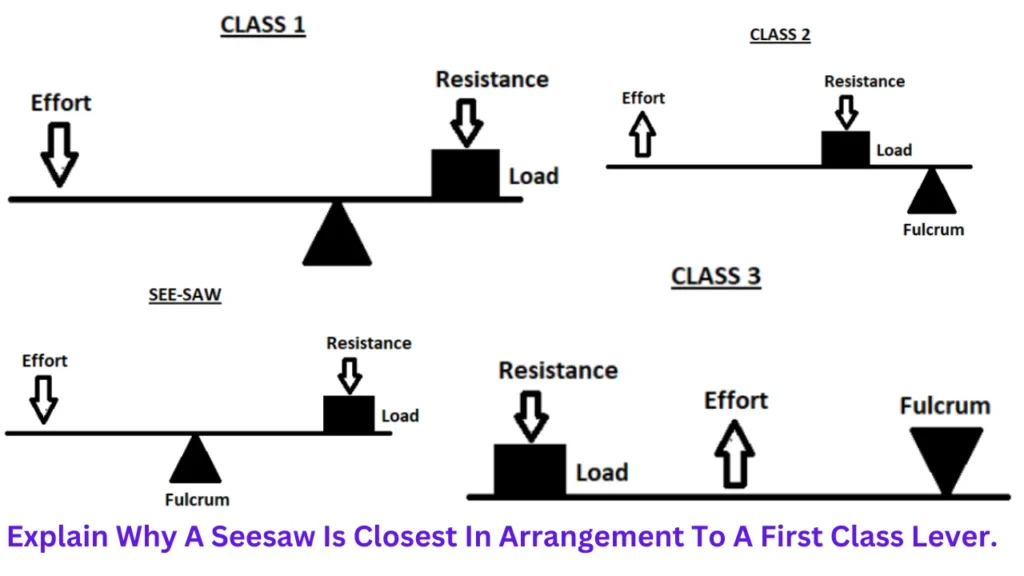

Understanding Lever Classes

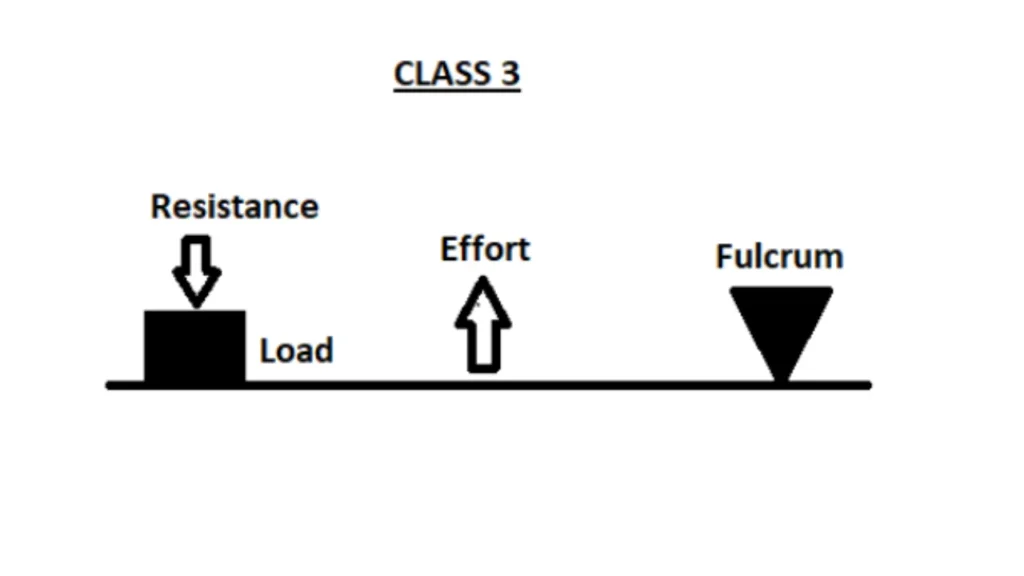

Levers are classified into three main types based on the position of the fulcrum, effort, and load. A first-class lever has the fulcrum positioned between the effort and the load. This arrangement allows for a balanced and efficient movement, making it a versatile tool in many applications. A second-class lever has the load between the fulcrum and the effort, while a third-class lever places the effort between the fulcrum and the load. Each class has unique characteristics and serves different purposes.

Explain why a seesaw is closest in arrangement to a first class lever.

To understand why a seesaw is closest in arrangement to a first class lever, it’s essential to analyze its structure and function. A seesaw consists of a long board balanced on a central pivot point, known as the fulcrum. Here’s how it fits the criteria of a first-class lever:

Position of the Fulcrum:

In a seesaw, the fulcrum is located at the center, with the board extending equally on both sides. This is the defining feature of a first-class lever, where the fulcrum is between the effort (force applied by a person) and the load (weight of the person on the other end).

Effort and Load:

The effort applied by one person to push the seesaw down is balanced by the load of another person on the opposite end. The seesaw will move up or down depending on the relative forces, similar to how a first-class lever operates.

Equal Distribution:

Because the seesaw is balanced at the fulcrum, any change in the position or force applied on one end will be directly felt on the other. This equal distribution is a key characteristic of first-class levers.

Comparing Seesaw to Other Lever Classes

To further explain why a seesaw is closest in arrangement to a first class lever, let’s compare it with other lever classes.

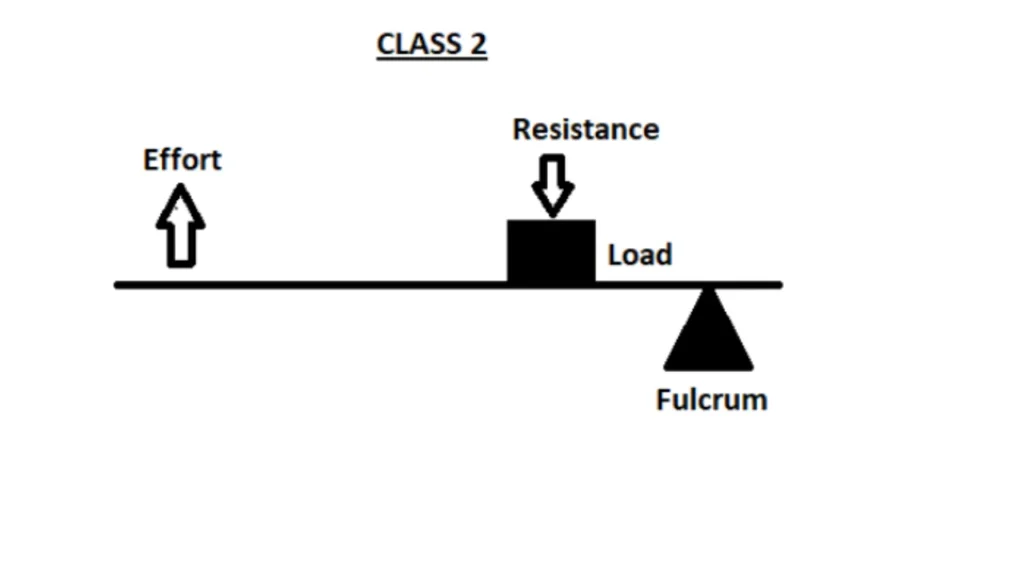

Second-Class Lever Example:

In a second-class lever like a wheelbarrow, the load is between the fulcrum (wheel) and the effort (handle). This configuration allows for a significant mechanical advantage but differs from the seesaw as the fulcrum is not central.

Third-Class Lever Example:

A pair of tongs serves as a third-class lever, where the effort is applied between the fulcrum (hinge) and the load (object being held). This arrangement is useful for precision but does not provide the balanced movement seen in a seesaw.

The seesaw’s fulcrum-centered configuration is unique to first-class levers, distinguishing it from the other two classes.

Practical Applications of First-Class Levers

The concept of a first-class lever, as demonstrated by a seesaw, is not limited to playgrounds. It has practical applications in various tools and machinery:

Scissors:

Like a seesaw, scissors have a central fulcrum with the effort applied on the handles and the load at the cutting ends. This design enables efficient cutting with minimal force.

Crowbars:

A crowbar acts as a first-class lever when the fulcrum (point of contact) is positioned between the effort applied by the user and the load (object being pried).

Balance Scales:

Traditional balance scales, used to measure weight, also operate as first-class levers, with the fulcrum at the center and weights applied on either side.

These examples highlight the versatility and efficiency of first-class levers in everyday tools.

The Physics Behind a Seesaw

To explain why a seesaw is closest in arrangement to a first class lever. We must delve into the physics involved. The primary principle at play is the law of the lever. The law of the lever states that the distance from the fulcrum and the applied force determine the rotational force (torque) around the fulcrum.

Torque Calculation:

To balance a seesaw, one person must exert the same torque as the other person. The formula for this balance is:

Torque=Force×Distance from Fulcrum

\text{Torque} = \text{Force} \times \text{Distance from Fulcrum}Torque=Force×Distance from FulcrumIf both individuals are at the same distance from the fulcrum and apply equal force, the seesaw remains in equilibrium.

Moment Arm:

In a seesaw, the moment arm is the length of the board from the fulcrum to the person. A longer moment arm increases the torque, affecting how the seesaw moves.

This physical principle underpins the operation of first-class levers and explains why a seesaw behaves as one.

Factors Affecting Seesaw Balance

While understanding why a seesaw is closest in arrangement to a first class lever. It’s also important to consider factors that affect its balance:

Weight Distribution:

If the weight of the two individuals is unequal, the heavier side will go down, as it exerts more force on the fulcrum.

Positioning:

Moving closer or farther from the fulcrum alters the moment arm, impacting the balance. A person further from the fulcrum has a greater effect due to increased torque.

Fulcrum Height:

The height of the fulcrum affects the ease of movement. A higher fulcrum results in more significant movement for the same applied force.

Freuquently Asked Questions

What makes a seesaw similar to a first-class lever?

A seesaw is similar to a first-class lever because its fulcrum is positioned in the center. With the effort applied on one side and the load on the other. This arrangement allows for balanced movement, just like a first-class lever.

How does a seesaw maintain balance?

A seesaw maintains balance by distributing the weight (load) and force (effort) equally on both sides of the fulcrum. If the force and weight are equal, the seesaw stays level.

What are other examples of first-class levers?

Other examples of first-class levers include scissors, crowbars, and balance scales. Where the fulcrum is between the effort and the load, similar to a seesaw.

Conclusion

In conclusion, a seesaw is closest in arrangement to a first class lever. Because of its central fulcrum placement and balanced distribution of effort and load. Its simplicity and effectiveness make it an ideal example to understand the fundamental mechanics of first-class levers. By analyzing the structure and function of a seesaw. We gain insights into the broader applications of levers in everyday life, from playgrounds to tools and machinery.